General

Even though DRANCO nv developed several anaerobic digestion processes on its own, the expertise of BCS covers all possible anaerobic digestion processes available worldwide. As a separate department, BCS offers a unique combination of both biological and mechanical/technical knowledge, allowing independent advice and guidance at each level of anaerobic digestion.

This team is active on new processes for Carbon Capture & Utilisation and developed the MEGACO process.

Services

The BCS team has more than 30 years of experience in:

- Analyses & lab-scale digestion tests (capacity: 150+ reactors)

- Process control & optimization

- Electromechanical support

- Automation

- Financial & process technical advice

DRANCO nv provides testing and consulting on two levels. On a first level the feasibility of the AD process for substrates can be evaluated. These tests cover the whole process chain from pretreatment over anaerobic digestion to post-treatment. These tests will provide all necessary information to elaborate a full-scale project.

On a second level DRANCO nv provides continuous assistance for full-scale plants (all types of AD technologies):

- Start-up of anaerobic digestion plants

- Revamping of unstable anaerobic digestion plants

- Maintaining a stable anaerobic digestion process

- Increasing performance of anaerobic digestion plants (increased loading rate and biogas yield)

In the US, DRANCO Inc. also assists clients in determining available incentives for their projects (grants, loans, tax credits, renewable energy and environmental credits) and then provides the services necessary to secure them, technical and economic feasibility studies, grant writing, grant administration, loan documentation preparation, power purchase agreement negotiation and administration, and negotiation of renewable energy and environmental credit contracts.

Tests

Feasability – Input material

To assure that the input substrates will have no adverse effect on the process, several parameters need to be analyzed, providing a first impression of the suitability of a product for anaerobic digestion.

Selection test

In case the waste contains impurities (e.g. municipal solid waste), a thorough pre-treatment will be necessary. A selection test will allow to evaluate this pre-treatment by sorting the waste in different fractions (plastics, glass, stone, sand, organics). This selection test provides the necessary info to decide what settings of the pre-treatment facility result in the most suited waste composition for AD.

Lab-scale silage test

Many input substrates are not year-round available for anaerobic digestion. In order to still allow for a continuous feeding to the AD-process, storage of these input substrates is necessary. Ensiling is a technique which has been successfully used in agriculture for many decades to preserve e.g. maize and grass.

OWS has developed a test that simulates the silage process on a small scale, which allows to investigate the effect of different silage conditions and additives for a specific substrate or combination of substrates. Also the effect of the silage process on the biogas and methane yield can be evaluated.

OWS has developed a test that simulates the silage process on a small scale, which allows to investigate the effect of different silage conditions and additives for a specific substrate or combination of substrates. Also the effect of the silage process on the biogas and methane yield can be evaluated.

Feasability – Anaerobic digestion process

When little information is known on the suitability of the substrates for anaerobic digestion, 2 important tests are available to evaluate if a substrate or a mixture of substrates can sustain stable fermentation.

Biogas Production Potential (BPP) test

Determines the maximum amount of biogas that can be produced from a given feedstock. The feedstock is incubated at 52°C (thermophilic) or 37°C (mesophilic) and is left to ferment batch wise. The volume of the biogas produced is measured and the amount of methane (CH4) and carbon dioxide (CO2) determined. This test provides a first estimation of a substrate’s potential for anaerobic digestion.

Lab-scale continuous fermentation test

Mimics full-scale fermentation of a single substrate or a combination of substrates. The test allows to optimize the digestion process on a long-term (input recipe, biogas productivity, organic loading rate, digestion temperature, toxicity, nutrient requirements,…) and provides the necessary info to go to a full-scale plant, eliminating the need for a more expensive pilot-scale testing. Testing can be performed at small scale (6L) and medium scale (60L).

Feasability – Digestate

The output after anaerobic digestion (as such or after post-treatment) can have many applications (direct use as fertilizer, compost after post-treatment, cover in landfilling,…). To evaluate what application offers the best options, it is important to analyse several parameters on the output. The selection of the necessary parameters happens in consultation with the client and will in many cases be determined by the legislation and quality standards in the country of application.

Following post-treatment steps can be tested in the lab:

- Post-fermentation test: Evaluates the potential rest biogas production of the digestate (needed to evaluate if a post-fermenter is economically feasible)

- Dewatering tests: selection of polymer, determination of characteristics of press cake/water or centrifuge cake/water, calculation of a mass balance

- Aerobic post-composting tests: evaluates the aeration, duration of post-composting, characteristics of final compost

- Wet separation test: simulates the SORDISEP technique on lab-scale, resulting in a mass balance and characterization of the different fractions, providing basic information whether SORDISEP is a suitable technology for the digestate in question and providing a basis for further dimensioning of the SORDISEP unit

Consultancy & support – Analytical assistance and biological supervision

Since the biological process is the heart of the anaerobic digestion plant, a good knowledge and monitoring of this process is crucial.

Analytical assistance

Monitoring of substrates

- TS-VS, Kj-N, C/N, COD,…

- Biogas Production Potential

- Nutrient content, heavy metals

- …

Digestion parameters

- TS-VS

- NH4+-N

- pH

- FOS, TAC

- VFA

- Viscosity

- …

Digestate characteristics

- Physico-chemical (TS-VS, pH, NH4+-N,…)

- Stability (AT4, O2-consumption, maturation,…)

- Fertilizer value

- …

Biological supervision

- Interpretation of analytical and operational parameters

- Follow-up and advice for optimal performance

- Highly flexible depending on the specific needs of the AD plant

- Daily, weekly, monthly,…

- Mail, phone,…

- On demand / on regular basis

Consultancy & support – Electromechanical support

Once the decision is made to start with anaerobic digestion, important choices have to be made regarding the necessary equipment (valves, pumps, agitators,…) and the most ideal configuration. Also in existing plants, optimization of the electromechanical equipment can lead to a more efficient process. OWS can offers assistance for both new and existing plants regarding:

- Assistance and follow-up of repairs

- Mechanical optimization

- Identification of malfunctions

- Control of operational safety

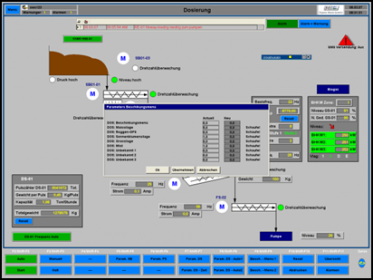

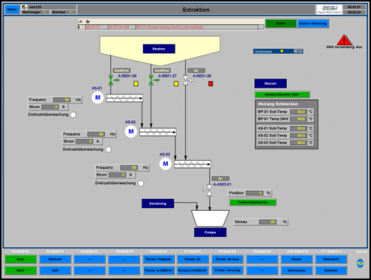

Consultancy & support – Automation

Based on the complexity of an installation, a well-designed automation can save many hours of work. An elaborated automation also allows to monitor various process parameters and interventions, making it more easy to understand the process and to recognize changes in an early stage. OWS can provide assistance with regard to:

- Improvement of automated controls

- Data management

- Long-distance control and intervention

References

All-round consultancy and support for more than 20 anaerobic digestion plants all over the world, covering both wet and dry, and thermophilic and mesophilic processes.

Three recent references are discussed in detail below:

- Verge grass (Flanders)

- Ecofuels (The Netherlands)

- Dutch Government (The Netherlands)

- Culver Duck Farms (US)

- AgriReNew (US)

- Homestead Dairy (US)